BMW DESIGNWORKS: More Than Just Cars

BMW Designworks is a jack of all trades studio in Newbury Park, California that tackles everything from concept cars and espresso machines to art installations and electric wingsuits. In this article, we'll take a deep dive into the products, stories, and people that make BMW Designworks tick.

The firm was established by industrial design heavyweight Chuck Pelly. The California native found work creating exhibits and toys for Mattel after graduating from Art Center College of Design in 1960. Pelly, seeking a broader understanding of the profession, left his company within a year's time. He traveled to Sweden and studied design at Konstfack. Upon returning to the United States, he found himself in the studio of the legendary Henry Dreyfuss. Here, Pelly spent a decade honing his skills and cramming his Rolodex with industry connections.

He was finally ready to make the leap. In 1972, he and two of his colleagues founded DesignworksUSA. The designers worked out of Pelly's garage in Malibu Canyon. This wasn't entirely because of economics. After years of trotting the globe and working nights, he wanted a situation where he'd be able to spend more time with his loved ones. The fledgling consultancy didn’t waste any time. They bought $500 worth of modeling clay and drawing paper and got to work.

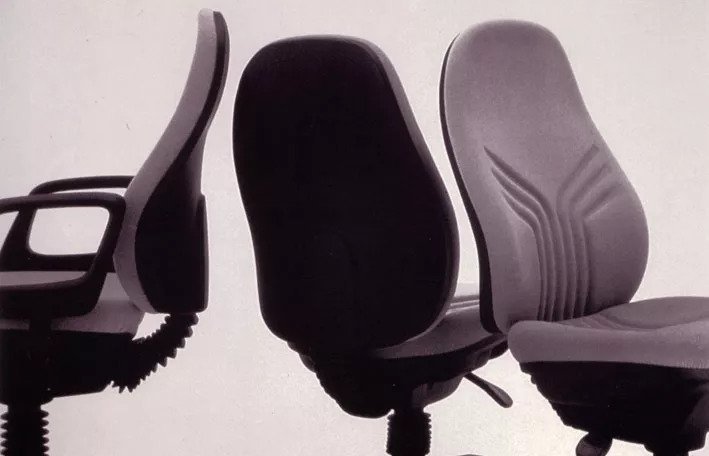

The trio took on a wide variety of projects in the early days as they bulked up their portfolio. Clients included Hyster, IMED, and The Otis Elevator Company. In 1976, they collaborated with watchmaker Microma on a line of digital watches. Designworks even ventured into environmental design when they created landscape proposals for Kampgrounds of America. They were able to carve out a niche pretty early on and built a solid reputation upon their seating designs.

It was in these years that they established relationships with Condi in California and Grammer in Germany. The C. Pelly Office Seating Collection has an aesthetic that is both futuristic and timeless as well as an emphasis on comfort and ergonomics. This collection first debuted in 1975 and remained on sale up until 2001.

Operations moved out of Pelly’s home in 1978. The team worked out of offices in Van Nuys and Agoura before settling on a site in Newberry Park in 1988. Designs still ran the gamut. Snowmobiles for Polaris, Purifiers for WaterPik, tractors for Steiger, and so on. Designworks also continued to provide seating solutions for a variety of industries. In 1984, they worked with Unitek on a line of high-end dental examination chairs. On the consumer side of things, they released the Crista collection for Sunar Hauserman the same year.

Companies in the automotive sector took note of Designworks’ efforts in seating design and commissioned them for projects of their own. General Motors worked with them on seats for the Corvette. This never amounted to much; only a single prototype was created, though I would argue that forming a relationship with GM at all was the most significant thing to come from this. They also collaborated with Chrysler and Volvo.

No doubt their biggest client during this time was BMW. In 1986, they called on the studio to come up with seats for their upcoming 8-series flagship coupe. The headrest is the most standout element here. In most cars, you’ll find it affixed to the seat with two bright metal bars. From humble subcompacts to ultra-luxurious saloons, they’re so widespread in the industry that they’re almost invisible. On the E31, the headrest is suspended above the seat. Part of the backrest extends out on one side to support it. Looking at the seat from the back, we can see a streamlined method of adjusting its height. This piece also houses the seat belt mechanism. It allows for easier entry into the car since it isn’t attached to the car frame itself.

This was the start of a long, fruitful partnership between the two. The firm assisted them with the development of seat designs, color patterns, and textures. The firm had $3 million in sales in 1990. Projects from BMW made up about half of this number. In August of 1991, BMW paid $4.5 million for a 50% stake in Designworks. In 1995, they paid an undisclosed amount for the rest of it.

The acquisition didn’t change much for the studio. They still possessed a generous level of autonomy. They stopped doing work for BMWs direct competitors in the automotive sector, but besides that, they still maintained ties with many of their clients. Designworks also still operates very much like a standalone business. A 2001 Los Angeles Times article touches on the unique dynamic between the two.

"The company is unique among automotive design houses in that it is a stand-alone profit center. When Chris Bangle, BMW’s Munich-based chief designer, asks Designworks to draw up proposals for a new 5-Series sedan, 'Designworks sends BMW a bill for the work,' (Bernhard Koehler, then chief of Designworks operations) said. “That makes us think very differently because we have to make a profit.”

The 78,000 square foot facility is split down the middle, so to speak. The auto designers are in the west wing and the product designers work out of the east wing. Employees of the respective sections are often moved between the two departments to expose them to different projects. Former Designworks president Adrian Van Hooydonk says that this method is critical to maintaining their multidisciplinary mastery.

The first major project after the acquisition to see the light of day was the Z07 concept, which debuted at the 1997 Tokyo Motor Show. The design is heavily inspired by the 1955 507 roadster. The horizontal kidney grille and the egg crate pattern inside are obvious indicators. The way the body kicks up around the edges of the front end also mimics the same area from its predecessor. We can also see similar vent treatment on the side. The Z07 also carves out an identity of its own. At the show, BMW unveiled two variants of the car. The convertible displays a bit of asymmetry with the wind tunnel behind the driver’s seat. The coupe has a distinctive bubble roof that dips smoothly at its center. The way the motion extends through the glass really sells the effect.

The car was a 5-year long project kicked off by Chris Bangle, then BMW's chief of design. The Z07s exterior designer was Henrik Fisker, a Danish designer who had been with the company since 1989. When Charles Pelley stepped down from his post in 1998, Fisker assumed responsibilities as president of Designworks.

Fisker’s tenure at the studio didn’t last long. In 2001, he left to head up design operations at Aston Martin. In his place was Adrian Von Hooydonk who had been with the company since 1992. He moved on to lead BMWs brand design studio in 2004. Verena Kloos took over for him and served as president until 2009. She was key in their expansion into Asia, which we’ll get into a bit later, and would go on to found a design consultancy of her own. Laurnenz Schaffer was president until 2016. Oliver Heimler had a short tenure at the position, only heading things until 2017 when he was transferred to MINI. Since then, Holger Hampf has seen things over. He has worked for the firm from 1998 to 2010 but had a layover in Munich as the head of Design User Experience of the entire BMW Group.

Operations expanded outside of their Newbury Park facility in 1998 when they opened a studio in Munich. Before this, executives would have to board a plane to Southern California to see how their projects were shaping up. Now they were only a short drive away from checking in.

BMW dug into the Chinese market by opening sites in Shanghai in 2006 and Singapore in 2012. Having facilities dotted across the world benefits them in a number of ways. Being active on three different continents means that at least one studio is open at all times. It’s no exaggeration to say that the work never stops at Designworks. These studios also produce localized versions of design proposals, which gives every project a unique perspective. Most importantly, it lends itself exceptionally to a level of diversity that few other studios can claim. At least 24 nationalities are represented across their three facilities and every major language is spoken. This also allows for designers to be exchanged between the different studios when needed.

In 2001, they worked on an art installation for Pinakothek de Moderna, one of the largest museums in the world dedicated to design and the applied arts. Their creation, dubbed “the art of car design,” is a celebration of the automotive development process. It featured a sculpture made of 30 tons of handpicked Carerra marble and a near-400-foot long hovering wall. There was also a six-monitor film installation about the design process and a selection of suspended vehicle parts.

Consumer electronics became a vital part of the business at the turn of the Millenium. They were integral in Nokia’s short-lived dominance over the cellphone market. Frank Nuovo started with Designworks in 1986 and quickly established a rapport with Nokia. Under his guidance, phones evolved from being mere appliances and became customizable extensions of their users. They churned out hits like the Nokia 101 in 1992, the 9100 in 1996, as well as the 5110 and 8810, which both debuted in 1998. They worked well together. So well, in fact, that Nokia actually hired Nuovo away from Designworks and named him their chief of design.

Most of their other electronics have been targeted toward the higher end of their respective markets. The Klipsch Palladium P39F line of loudspeakers debuted in 2007, at the perfectly reasonable price of $20,000 a pair. The Nilfisk Coupe and Power Extreme vacuum cleaners are apparently so expensive that they won’t even TELL me how much they are. The Starbucks Sirena espresso machine is a more palatable proposition

It was developed alongside the coffee chain and Saeco, a leading coffee machine manufacturer. They developed 7 design concepts ranging from retro to contemporary to what they define as “progressive alternative.” From these, 4 of them were taken further into development. Ultimately, they went with the final design because of its American art-deco styling. It has a soft geometry with a bevy of curves, circles, and rounded edges. There’s hardly a corner on the thing. It sought to bring cafe-quality drinks to the home, with features such as a rapid steam boiler, commercial-grade portafilter, and a patented back-pressure adapter that automatically adjusts to the coffee's grind. The Starbucks Sirena was available online and in select corporate stores in November 2007 at a price of $600.

They’ve experimented with hydrogen-powered vehicles. In 2008, they presented the Hydrogen Salt Flat Racer as part of the 2008 LA Auto Show Design Challenge. The brief for it was “what would eco-friendly race cars look like in the year 2025. Designers leaned into the concept of “reusability.” The wheels are repurposed barbeque lids and the body is an oil barrel. Its wheels are made of a nylon gel, which provides a bit of flex and allows them to be airless. Sustainability was also a major sticking point, so much so that they were said to have put multiple goldfish into its tank to prove its environmental friendliness.

If you’re looking for something a bit closer to reality, then look no further than the H2R. The company was set to release a hydrogen-powered variant of the 7-series, but before it did, they wanted to give a taste of what the technology could be truly capable of. It was completed in a span of 10 months under the direction of Research and Technology CEO Dr. Raymond Freymann. When Designworks came into the picture, they were set on making it as aerodynamic as possible. The teardrop plan view, kammback tail, and covered rear wheels bring the coefficient of drag down to just .21. It measures 17.5 feet long, but thanks to the aluminum space frame and extensive use of carbon fiber reinforced plastic, the H2R has a curb weight of just under 3,500 pounds.

It was taken to the Miramas Proving Grounds in France, where it set 9 land speed records. An impressive feat, but it didn’t do much to prop up the Hydrogen 7 that was released for the 2007 model year. It was more of a proof of concept than anything else. Production ended at the end of the year and just 100 were built in total.

Out of everything we’ve covered so far, the BMW GINA is possibly the most innovative product to ever come out of Designworks. The name is an acronym for “Geometry and Functions in N Adaptations.” The N in this equation stands for infinite, and the whole title is a way of conveying the countless ways that cars may function and be assembled altogether. Instead of body panels, the GINA consists of just 4 main sections. One piece goes from the front end to the end of the doors. There’s also a pair at either corner of the quarter panel. The final one is across the rear deck.

Don’t think of the exterior of the GINA as metal. Consider the water-resistant, wire mesh, polyurethane-coated spandex a “skin” that is stretched over an aluminum and carbon skeleton. Lastly, the car has the ability to alter or even completely conceal major components. The headlights and tail lights sink into the body when not in use. It also does away with a clunky latched hood. The engine is accessed through an opening in the center of the bonnet. The seats, steering wheel, and instrument cluster can also change depending on the situation.

Austrian base jumper Peter Salzmann and a friend discussed the ways in which he could improve wingsuit performance. One of their ideas was to incorporate a supporting motor in some capacity. He worked in his garage in the following weeks on the concept. He had four main points that he wanted to hit on. He wanted to increase his gliding time, take off from greater heights, increase the distance in which he could fly out, and be able to come to a safe stop when it was over.

After working on this on his own for a bit, he contacted BMW to take it to the next step. It was during these initial talks that the idea became more fleshed out. Electric motors were chosen because they were compact enough to be attached to a regular wingsuit and they didn’t generate much heat.

They used cardboard mockups to get a rough idea of things and aluminum prototypes to gain a more grounded perspective on things. From these, they made a few more modifications to the design. The propulsion unit was originally going to be on the back, but it was decided later to move it to the front. The impeller they wanted to use ended up being too heavy and would restrict mobility. They switched their focus toward a smaller unit that made 40% less power, but also provided them with the mobility they desired. It weighed about 26 pounds and housed 2 carbon fiber impellers.

The initial tests were run in a horizontal wind tunnel. Dummies were used to fine-tune the placement of various components. After this, the team traveled to Sweden to test it inside a skydiving tunnel. This is the only place in the entire world where a wingsuit pilot can fly indoors. The design was tweaked even further. Inlets were added to increase air flow. Weight was reduced. The throttle was relocated so the operator could more easily access it with their middle and ring fingers.

After years of development, the time had come to show their creation off to the world. They originally planned on debuting it in South Korea in Spring 2020 but the global situation left them scrambling to come up with another location. A new spot in Austria was founded months later. The flight was a rousing success. Salzmann broke multiple records and even reached speeds of 186 miles per hour. Most importantly, he was able to land safely in the end.

BMW Designworks is unlike any other studio in the auto industry. Through hard work and dedication, they moved out of a garage and into a sprawling complex in Newberry Park. Their multidisciplinary nature gives their parent company a perspective that no other automaker can claim. From cars and consumer electronics to examination chairs and electrified wingsuits, it’s impossible to predict what will come out of Designworks next.